Blog

- Home

- Blog

The Ultimate Guide to Choosing the Best Cable Tray for Cable Management in 2025

In the rapidly evolving world of electrical installations, selecting the right cable management solutions is crucial for efficiency and safety. As we move into 2025, the demand for effective cable management continues to rise, making it essential for industry professionals to stay informed about the latest advancements in cable tray systems. Renowned expert in cable management, Dr. Emily Carter, emphasizes, "The key to a successful installation lies in choosing the right cable tray cable, which not only organizes but also protects your wiring infrastructure."

In this ultimate guide, we will delve into the various factors to consider when selecting the best cable tray for your needs. From understanding load capacities to evaluating materials and environmental factors, this guide aims to provide comprehensive insights that will help you make informed decisions. As the industry embraces new technologies and practices, the versatility and efficiency of cable tray systems become more apparent, ensuring that your cable management setup meets both current and future demands.

Stay ahead of the curve as we explore the essential elements of cable tray cables and their role in optimizing your cable management systems. Remember, the right choice can prevent future headaches and contribute to a streamlined, safe, and efficient environment for your electrical needs.

Understanding Cable Management: Importance and Industry Standards

Effective cable management is crucial for any organization looking to maintain safety, efficiency, and reliability in its operations. As we move into 2025, industry standards emphasize the importance of organizing and securing cabling systems to prevent hazards such as tripping, equipment damage, and interference in data transmission. According to the National Fire Protection Association (NFPA), improperly managed cables can contribute to fire hazards, with around 30% of electrical fires in commercial buildings linked to faulty wiring and cable management issues. This underscores the need for rigorous adherence to industry standards, ensuring that all installations comply with the National Electrical Code (NEC) and International Electrotechnical Commission (IEC) guidelines.

In addition to safety, effective cable management aids in optimizing space and accessibility. The Bureau of Labor Statistics indicates that businesses could experience up to a 25% increase in operational efficiency by implementing organized cable systems. Properly designed cable trays not only facilitate quicker access for maintenance but also allow for better airflow, reducing the risk of overheating in critical infrastructure. Additionally, as the trend toward remote and hybrid work environments grows, ensuring that cabling in offices is well-managed enhances the aesthetics and user experience, making environments more conducive to productivity. For organizations planning their cable management strategies in the coming years, adherence to these industry standards is essential for fostering safety, efficiency, and a compliant workspace.

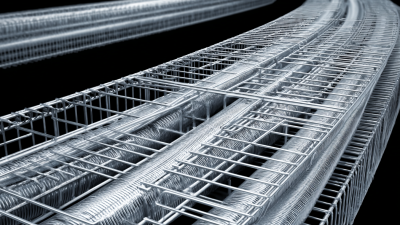

Types of Cable Trays: Comparing Materials and Designs for 2025

When selecting the best cable tray for effective cable management in 2025, understanding the various types of cable trays and their materials is crucial. Metal cable trays, commonly made from steel or aluminum, offer durability and strength, making them ideal for industrial environments. They are resistant to corrosion and can withstand heavy loads, ensuring long-term reliability. Additionally, metal trays often allow for better thermal dissipation, which is essential for managing heat produced by high-performance cables and electronic equipment.

On the other hand, non-metallic cable trays, typically composed of fiberglass or PVC, present a lightweight alternative with unique advantages. These materials are inherently corrosion-resistant and non-conductive, making them suitable for environments prone to moisture or chemical exposure. The design flexibility of non-metallic trays allows for innovative shapes and configurations, which can be beneficial in complex installations where adaptability is essential. Furthermore, their lower weight can simplify installation processes and reduce labor costs.

In 2025, the choice between metal and non-metallic trays will depend on specific application requirements, including load-bearing needs, environmental conditions, and installation preferences. Understanding the strengths and weaknesses of each material can assist in making an informed decision that enhances both safety and efficiency in cable management systems.

The Ultimate Guide to Choosing the Best Cable Tray for Cable Management in 2025

| Type of Cable Tray | Material | Load Capacity (lbs) | Installation Difficulty | Best Use Case |

|---|---|---|---|---|

| Ladder Tray | Steel | 1500 | Medium | Heavy-duty applications |

| Wire Mesh Tray | Aluminum | 600 | Easy | Data centers, light cabling |

| Solid Bottom Tray | PVC | 300 | Easy | Indoor locations with light cables |

| Cable Ladder Tray | Galvanized Steel | 2000 | Hard | Outdoor, industrial use |

| Trough Tray | Stainless Steel | 800 | Medium | Chemical processing, food industry |

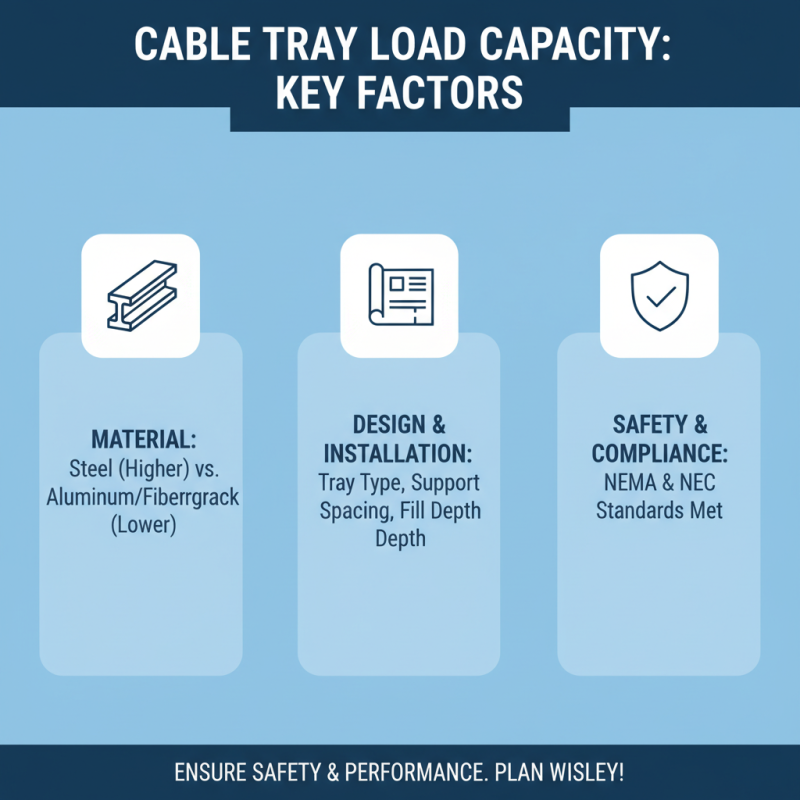

Load Capacity Considerations: Ensuring Safety and Compliance

When selecting a cable tray for effective cable management, understanding load capacity is crucial to ensure safety and compliance with industry standards. According to the National Electrical Manufacturers Association (NEMA), the load capacity of cable trays is often determined by their material, design, and installation method. For example, steel trays typically have a higher load capacity compared to those made from aluminum or fiberglass. A well-planned load capacity not only affects the tray's performance but also ensures that it meets the National Electrical Code (NEC) guidelines, which outline the minimum safety standards for electrical installations.

To ensure you're choosing the right cable tray, consider calculating the total weight of cables and any additional wiring that may be added in the future. An industry study by the International Electrotechnical Commission (IEC) states that an overloaded cable tray can lead to overheating, resulting in potential hazards. It’s essential to adopt a conservative approach and account for up to 20% additional capacity to accommodate future expansions.

**Tips:** Regular inspections of your cable tray system can prevent overloaded situations. Keep an eye on cable strain and wear, and conduct periodic assessments to ensure that the used materials meet the latest safety compliance standards. Utilizing software tools for load calculations can also enhance accuracy and aid in making informed decisions about your cable management solutions.

Installation Best Practices: Maximizing Efficiency and Aesthetics

When it comes to installing cable trays, ensuring an efficient and aesthetically pleasing setup requires careful planning and adherence to best practices. According to the National Electrical Contractors Association (NECA), proper cable management can improve system reliability and reduce maintenance costs by up to 30%. This is particularly crucial in large facilities where tangled cables can lead to downtime and increased troubleshooting time. Therefore, before installation, conducting a thorough assessment of the project's requirements, including load capacity and environmental factors, is essential.

Additionally, optimizing the layout of cable trays can enhance both functionality and appearance. Research from the Electrical and Electronics Engineers (IEEE) suggests that strategic placement of cable trays enhances airflow and reduces heat accumulation, which extends the lifespan of electrical systems. Furthermore, using color-coded trays not only organizes cables aesthetically but also increases efficiency during maintenance, as technicians can readily identify the necessary connections. Attention to detail in these aspects—such as ensuring proper spacing between trays, securing them adequately, and using compatible materials—can significantly enhance the overall installation process while maintaining a neat and professional appearance.

Future Trends in Cable Tray Technology: Innovations to Watch in 2025

As we look ahead to 2025, the cable tray industry is poised for significant advancements driven by technological innovations and increasing demands for efficient cable management. One of the most notable trends is the integration of smart technologies into cable tray systems. According to a recent industry report by MarketsandMarkets, the global market for smart cable management solutions is expected to reach USD 5 billion by 2025, growing at a CAGR of over 15%. Smart trays equipped with sensors can monitor cable health, track inventory levels, and provide real-time status updates, facilitating proactive maintenance and minimizing downtime in critical operations.

Another emerging trend is the emphasis on sustainability in cable tray design and materials. The shift towards eco-friendly manufacturing processes is becoming increasingly important as companies seek to reduce their carbon footprints. A report by Grand View Research indicates that the adoption of recycled materials in industrial applications, including cable management, is projected to grow significantly, with sustainable solutions becoming a key differentiator in the market. This movement not only benefits the environment but also aligns with corporate social responsibility initiatives, thus meeting the expectations of an increasingly eco-conscious consumer base.

In addition, modular cable tray systems are gaining traction due to their flexibility and ease of installation. These modular designs offer customizable configurations that can adapt to various environments and cable types, particularly in rapidly evolving technological landscapes such as data centers and industrial facilities. The ability to reconfigure and expand these systems easily will address future challenges posed by increasing data traffic and the need for rapid deployments. As these trends take shape in 2025, organizations will need to stay informed and adaptable to select the most innovative and efficient cable management solutions.

Related Posts

-

Maximizing Safety and Efficiency: The Essential Guide to Choosing the Right Cable Trunking Solutions

-

Understanding the Benefits of Cable Tray Systems for Modern Electrical Installations

-

10 Best Wire Mesh Cable Tray Solutions for Efficient Cable Management

-

Exploring Cable Fences Innovations at the 138th Canton Fair in 2025

-

What is Fence Netting and How Can It Benefit Your Outdoor Space

-

Understanding the Unique Benefits of Cable Mesh for Your Industrial Applications