Blog

- Home

- Blog

Top 10 Benefits of Using Tray Cable for Electrical Installations

In the realm of electrical installations, choosing the right type of cable is paramount to ensuring safety, efficiency, and durability. Among the various options available, tray cable has emerged as a preferred choice for many professionals in the industry. This specialized type of cable is designed specifically for use in industrial and commercial settings, providing a reliable solution for power distribution and networking applications. Its robust construction allows for flexibility and ease of installation, making it a practical alternative for those working in environments where traditional cables may fall short.

The benefits of utilizing tray cable extend beyond mere convenience; they encompass enhanced protection against environmental factors, reduced installation costs, and improved overall system performance. With its ability to withstand harsh conditions and resist corrosion, tray cable is particularly well-suited for applications in factories, warehouses, and other demanding settings. This introductory exploration will delve into the top ten advantages of using tray cable for electrical installations, highlighting why it continues to gain traction among electricians and engineers seeking dependable and efficient solutions.

Benefits of Tray Cable in Electrical Installations

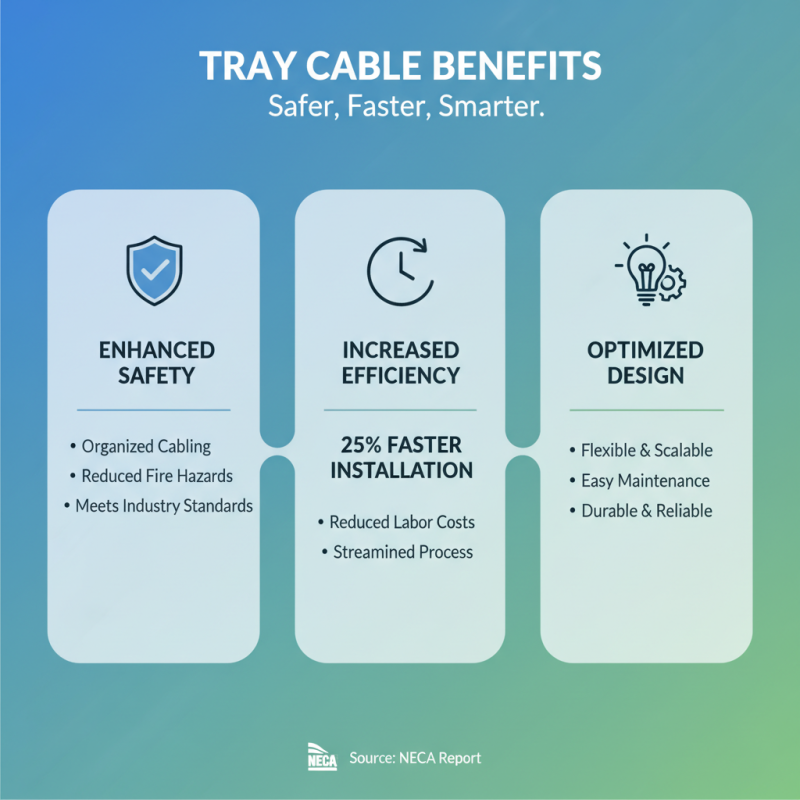

Tray cable has become a favored choice in electrical installations due to its myriad benefits, particularly when it comes to enhancing both safety and efficiency. The architectural design of tray cable allows for a more organized and streamlined installation process, which can significantly reduce labor costs. According to a report by the National Electrical Contractors Association (NECA), the use of tray cables can cut installation times by up to 25%, ensuring that projects are completed more swiftly without compromising quality.

In addition to efficiency, tray cables offer superior flexibility and adaptability for various applications. These cables are constructed to withstand environmental stresses, making them ideal for industrial settings where exposure to chemicals or extreme temperatures may occur. Furthermore, they are easier to route and support through complex infrastructures. A study published in the Journal of Cable Management highlights that businesses utilizing tray cable report 30% fewer maintenance issues compared to traditional wiring methods.

**Tips:** When planning an electrical installation, it's crucial to assess the specific needs of your project, including the environment and potential future expansions. Another important consideration is to consult local electrical codes, as some jurisdictions may have specific regulations regarding tray cable use. Taking these factors into account will help maximize the advantages that tray cable can provide.

Enhanced Flexibility for Complex Wiring Needs

Tray cables are increasingly favored in electrical installations due to their enhanced flexibility, making them ideal for complex wiring needs. This flexibility allows for easier routing through intricate layouts and provides the adaptability necessary for projects that require frequent adjustments or updates. Whether you're working in commercial buildings, manufacturing facilities, or residential settings, tray cables offer the versatility to navigate tight spaces and varied environments with ease.

Tips: When planning an installation, consider the type of environment the cables will be exposed to. Selecting tray cables designed for specific conditions, such as moisture or heat, can prevent potential hazards and ensure longevity. Additionally, maintain a clear cable layout to facilitate easier modifications in the future, allowing for seamless upgrades and changes as your wiring needs evolve.

Using tray cables can also simplify maintenance. Their design allows for quick access to wires without the need for excessive downtime, ensuring that repairs can be conducted swiftly, reducing disruptions to productivity. Remember to label your cables properly during installation. This practice can save time and provide clarity, especially in complex setups where many wires coexist.

Improved Durability and Long-Term Performance

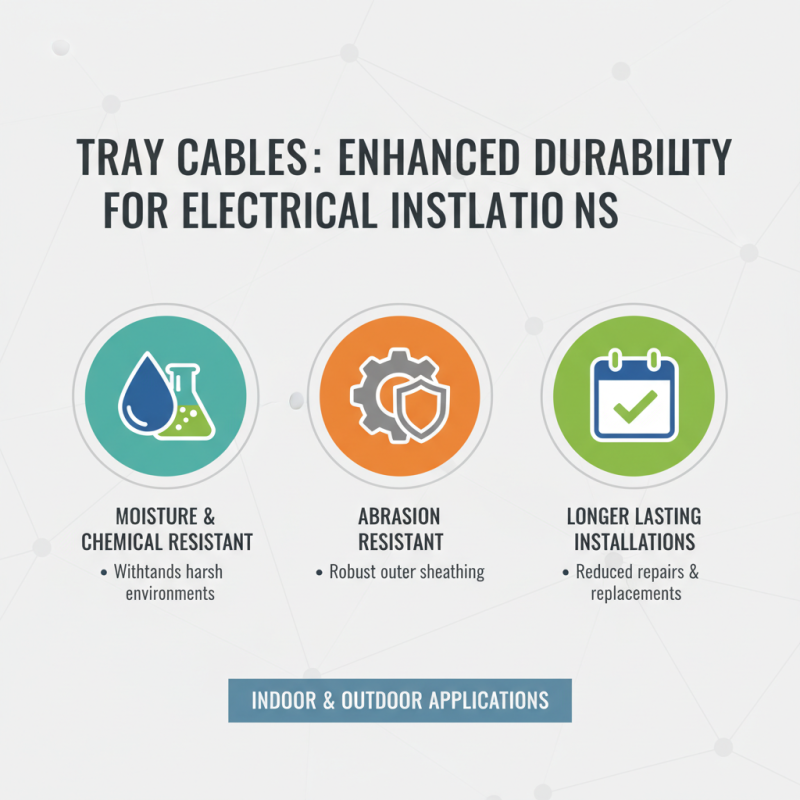

Tray cables, known for their robust construction, significantly enhance durability in electrical installations. Unlike traditional wiring methods, tray cables are designed to withstand harsh environmental conditions, making them ideal for both indoor and outdoor applications. Their outer sheathing is typically made of materials that are resistant to moisture, chemicals, and abrasion, ensuring that they can endure the rigors of various settings without compromising their integrity. This robustness translates into longer-lasting installations, reducing the need for frequent repairs or replacements.

In addition to their resistance to physical damage, tray cables offer long-term performance advantages by maintaining consistent electrical properties over time. The layered construction minimizes the risk of signal interference and energy losses, which is especially critical in complex electrical systems. As a result, users can expect more efficient operation and reduced downtime, which ultimately contributes to lower maintenance costs. Investing in tray cables not only ensures immediate safety and reliability but also supports the longevity of electrical systems, making them a smart choice for any installation project.

Cost-Effectiveness in Large-Scale Projects

Using tray cables in electrical installations presents substantial cost-effectiveness, particularly in large-scale projects. Tray cables are designed to be versatile and durable, allowing for easier management and installation processes, which can significantly reduce labor costs and time. Their design accommodates multiple conductors within a single cable, leading to fewer materials needed over large distances, thus presenting a more economical solution than traditional wiring methods.

When planning a large electrical installation, consider these tips to maximize the cost-effectiveness of tray cables. First, evaluate the layout of your installation to determine the most efficient routing for cables; this can help minimize waste and prevent unnecessary expenses. Additionally, using the appropriate size and type of tray cable can enhance both performance and longevity, reducing the need for replacements or repairs down the road.

Another crucial aspect is the reduced maintenance costs associated with tray cables. Their robust structure and protective design mean that they are less prone to damage or wear, which directly impacts long-term project budgets. By ensuring that your installation utilizes tray cables correctly, you can achieve substantial savings and improve overall project efficiency.

Top 10 Benefits of Using Tray Cable for Electrical Installations - Cost-Effectiveness in Large-Scale Projects

| Benefit | Description | Cost Impact | Installation Time |

|---|---|---|---|

| Durability | Tray cable is built to withstand harsh environments, reducing replacement costs. | Low | Fast |

| Flexibility | Easily configured to meet project needs without extensive modifications. | Moderate | Quick |

| Reduced Labor Costs | Simplified installation reduces the need for skilled labor. | Significant | Short |

| Versatility | Can be used in various applications across many industries. | Moderate | Flexible |

| Compliance | Meets various electrical codes, ensuring project safety. | Low | N/A |

| Space Saving | Compact design requires less physical space for installation. | Low | Quick |

| Resistance to Environmental Factors | Designed to resist moisture, chemicals, and temperature variations. | Low | Moderate |

| Lower Overall Costs | Cost-effective over time due to reduced maintenance and replacement. | High | N/A |

| Scalability | Easily scalable for future expansions of projects. | Moderate | Flexible |

| Enhanced Safety | Improved safety features can lower insurance costs and liability. | Moderate | N/A |

Streamlined Installation Process for Efficiency

Using tray cables for electrical installations offers a streamlined installation process that significantly enhances efficiency. One of the core advantages of tray cables is their design, which allows multiple conductors to be bundled together, reducing the complexity of wiring layouts. This bundling not only simplifies the organization of cables but also minimizes the time spent on installation, as electricians can quickly run a single line instead of multiple separate wires. The lightweight nature of tray cables also contributes to easier handling and maneuverability during installations.

Moreover, the flexibility of tray cables makes them highly adaptable for various applications. They can be easily routed through tight spaces or around obstacles without compromising their integrity or performance. This adaptability further accelerates the installation process because electricians can quickly adjust cable paths as needed, all while ensuring compliance with regulatory and safety standards. Ultimately, the use of tray cables not only speeds up the installation timeline but also enhances the overall efficiency of electrical projects, making them a preferred choice for many professionals in the field.

Top 10 Benefits of Using Tray Cable for Electrical Installations

Related Posts

-

Ultimate Guide to Wire Tray Options for Industrial Applications

-

How to Choose the Right Welded Wire Mesh for Your Construction Projects

-

7 Reasons Why Welded Wire Fences Are Essential for Security and Durability

-

Challenges Faced While Sourcing Wire Mesh Panels: A Global Procurement Perspective

-

Maximizing Safety and Efficiency: The Essential Guide to Choosing the Right Cable Trunking Solutions

-

The Essential Guide to Understanding the Benefits of Welded Mesh in Modern Construction