Blog

- Home

- Blog

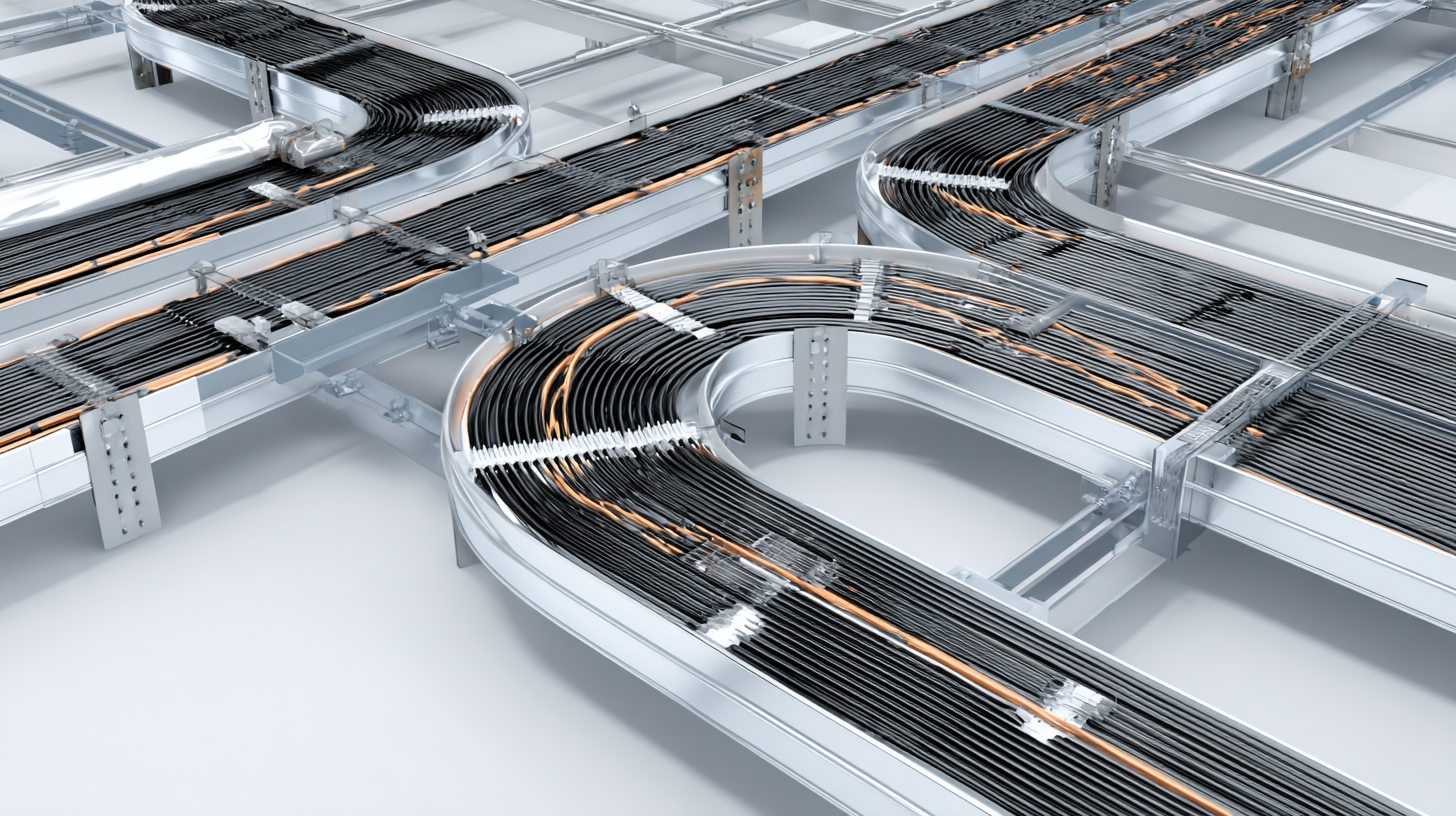

Understanding the Benefits of Cable Tray Systems for Modern Electrical Installations

In today's rapidly evolving electrical landscape, cable tray systems have emerged as a crucial component for modern installations, offering enhanced organization, efficiency, and safety. According to a report by Grand View Research, the global cable tray market size was valued at USD 4.5 billion in 2021, with an expected compound annual growth rate (CAGR) of 6.8% from 2022 to 2030. This growth highlights the increasing reliance on cable management solutions to support infrastructure development across various sectors, including commercial, industrial, and telecommunications.

Cable tray systems provide a myriad of benefits, such as improved cable protection, simplified maintenance, and greater scalability for expanding electrical needs. For instance, the National Electrical Contractors Association (NECA) indicates that the proper utilization of cable tray systems can reduce installation time by up to 50%, allowing for quicker project completions and minimized labor costs. These systems not only streamline the organization of cabling but also facilitate easier access for inspection and troubleshooting, ultimately leading to increased operational reliability.

Cable tray systems provide a myriad of benefits, such as improved cable protection, simplified maintenance, and greater scalability for expanding electrical needs. For instance, the National Electrical Contractors Association (NECA) indicates that the proper utilization of cable tray systems can reduce installation time by up to 50%, allowing for quicker project completions and minimized labor costs. These systems not only streamline the organization of cabling but also facilitate easier access for inspection and troubleshooting, ultimately leading to increased operational reliability.

With the rising complexity of electrical installations, the adoption of cable tray systems is vital for ensuring compliance with safety standards and enhancing the longevity of electrical systems. As organizations seek to optimize their electrical infrastructure, understanding the advantages of cable tray systems is essential for making informed decisions that promote safety, efficiency, and cost-effectiveness in modern installations.

How to Select the Right Cable Tray System for Your Electrical Needs

When selecting the right cable tray system for your electrical needs, several key factors should be considered. First, assess the type and volume of cables that will be accommodated. Different applications, such as industrial or commercial installations, may require distinct tray designs to support varying cable sizes and weights. Choosing a tray that can handle the maximum anticipated load ensures both safety and efficiency.

Additionally, the environmental conditions where the cable tray will be installed must be evaluated. Factors like moisture, temperature fluctuations, and exposure to chemicals can greatly influence the material selection. Opting for trays made from corrosion-resistant materials or those with appropriate coatings can enhance longevity and reduce maintenance costs. Furthermore, consider the ease of installation and flexibility of the tray system, as modular designs can simplify modifications and expansions in the future. By carefully considering these elements, you can select a cable tray system that meets both current and future electrical needs effectively.

How to Install Cable Tray Systems Effectively for Optimal Performance

Installing cable tray systems effectively is crucial for optimal performance in modern electrical installations. According to a report by the National Electric Contractors Association (NECA), well-designed cable management systems can improve installation efficiency by up to 30%, significantly reducing labor costs. Proper planning and layout are essential; install trays in areas that allow easy access for maintenance and modification. By considering factors like future expansion needs and the weight of the cables, installers can prevent congestion and ensure safety.

When it comes to installation techniques, utilizing the right tools and materials is vital. A study published by the Electrical Engineering Research Journal emphasizes the importance of using high-quality materials, indicating that proper material selection can enhance durability and reduce the risk of cable damage. Adopting standardized practices, such as maintaining the correct spacing and supporting the trays at specified intervals, can further optimize the system's performance. This meticulous approach not only extends the lifespan of the cable trays but also ensures compliance with industry regulations.

How to Maximize Safety and Compliance with Cable Tray Installations

Effective installation of cable tray systems is crucial for ensuring safety and compliance within modern electrical infrastructures. Cable trays provide a structured pathway for electrical wiring, which helps reduce the risks associated with loose or disorganized cables. This system not only minimizes hazards such as electrical fires but also improves maintenance efficiency by allowing easy access for inspections and repairs. By complying with industry standards in installation practices, users can further enhance safety, ensuring that cables are securely supported and properly insulated.

In the context of the growing market for Fiber Reinforced Polymer (FRP) cable trays, significant benefits can be derived by adopting this material over traditional alternatives. FRP offers superior corrosion resistance, which is vital in environments prone to moisture and chemicals. As the demand for FRP cable trays is projected to expand considerably over the next decade, it positions itself as a sustainable and compliant choice for electrical installations, ultimately leading to enhanced operational longevity and reduced overall costs for businesses in the long run.

Understanding the Benefits of Cable Tray Systems for Modern Electrical Installations

| Feature | Description | Benefits |

|---|---|---|

| Material Variety | Available in steel, aluminum, and fiberglass | Durability and corrosion resistance, suited for various environments |

| Ease of Installation | Modular design allows for quick setup | Reduced labor costs and installation time |

| Cable Management | Organizes and supports multiple cables effectively | Improves safety and ease of maintenance |

| Compliance | Meets various safety and electrical codes | Helps avoid fines and ensures legal compliance |

| Flexibility | Easily reconfigured for changing needs | Adapts to new technologies and layouts |

How to Maintain and Inspect Cable Tray Systems for Longevity

Effective maintenance and regular inspection of cable tray systems are vital for ensuring their longevity and performance in modern electrical installations. According to a report by the National Electrical Manufacturers Association (NEMA), properly maintained cable tray systems can extend their service life by up to 20%, significantly reducing replacement costs. Regular visual inspections should include checking for signs of wear, corrosion, and structural integrity. It is recommended to perform these inspections at least twice a year, especially in environments with high humidity or chemical exposure.

Additionally, cleaning the trays to remove dust, debris, and other contaminants is crucial for optimal performance. The Electrical Safety Foundation International (ESFI) suggests establishing a maintenance schedule that includes inspections and cleanings, which can prevent costly downtimes and enhance safety. Implementing a proactive maintenance plan can detect potential issues before they escalate, providing a safer and more reliable electrical system. For organizations, following these guidelines not only ensures compliance with safety regulations but also promotes a more efficient operation, safeguarding both employees and assets.

How to Integrate Cable Trays with Other Electrical Management Solutions

Integrating cable trays with other electrical management solutions can significantly enhance the efficiency and safety of electrical installations. According to the National Electrical Contractors Association (NECA), proper integration of cable management systems can reduce installation time by up to 30%, contributing to lower labor costs and fewer disruptions during the construction process. Cable trays not only provide support and organization for wiring but when combined with other systems like conduit and raceways, they can help optimize space utilization and improve accessibility for future maintenance.

Moreover, the combination of cable trays with fire-resistant barriers can enhance safety compliance. A report by the National Fire Protection Association (NFPA) indicates that properly managed cabling systems can reduce the risk of fire incidents by ensuring that cables are not overcrowded or improperly routed. This integration also allows for better segregation of power and data cables, minimizing electromagnetic interference and increasing overall system performance. By leveraging these synergies, businesses can achieve a more robust electrical infrastructure, ensuring reliability while meeting regulatory standards.

Related Posts

-

Maximizing Safety and Efficiency: The Essential Guide to Choosing the Right Cable Trunking Solutions

-

7 Reasons Why Welded Wire Fences Are Essential for Security and Durability

-

Evaluating the Benefits of Welded Wire Mesh Fence Against Traditional Fencing Solutions

-

Exploring Cable Fences Innovations at the 138th Canton Fair in 2025

-

Unveiling Industry Trends for Cable Racks at the 138th China Import and Export Fair 2025

-

8 Reasons Why Mesh Wire Is Essential for Modern Industrial Applications